Twin gourds

Source manufacturer

technological innovation

High cost performance ratio

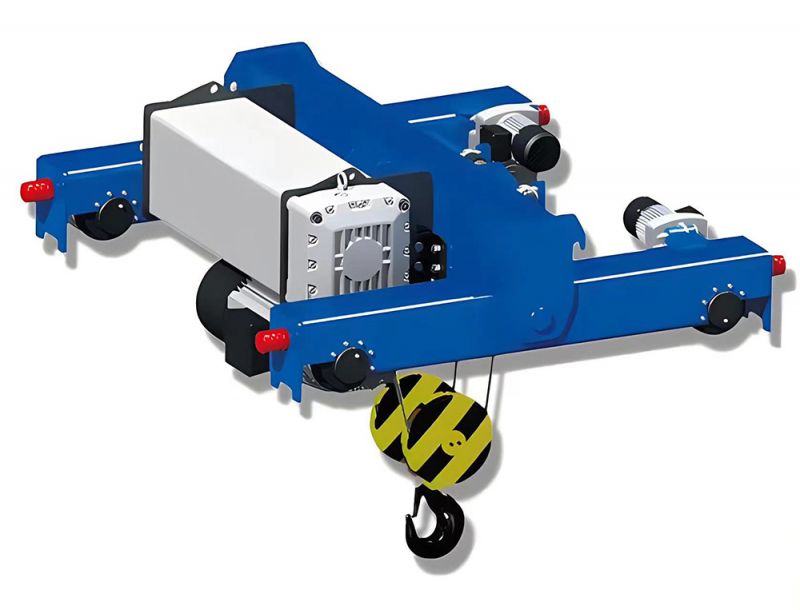

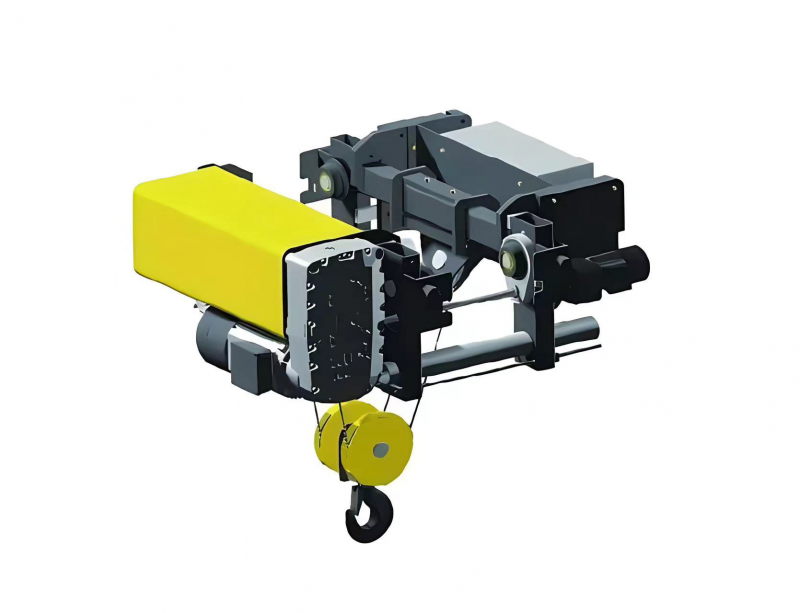

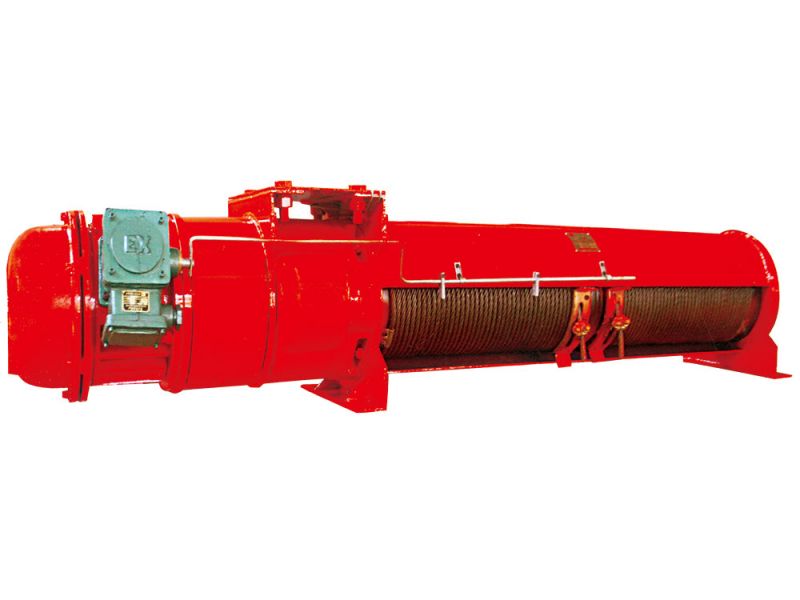

Electric hoist is a special lifting equipment installed on overhead cranes and gantry cranes. It has the characteristics of small size, light weight, simple operation, and convenient use, and is used in industrial and mining enterprises, warehouses, docks, and other places.The electric hoist has a compact structure, and the electric hoist with the motor axis perpendicular to the drum axis adopts a worm gear transmission device. Its disadvantages are: large length, large width, bulky structure, low mechanical efficiency, and difficult processing. The hydraulic system has dual control, and both the overflow regulating valve and the magnetic contact pressure gauge can accurately control the pressure. The electrical control department has adopted low voltage control to increase the safety of the control system.Main featuresThe structure and characteristics of the wire rope electric hoist: The machine adopts an integrated mechanical and electrical design. By replacing different molds, different specifications of wire ropes can be pressed, making it easy and safe to handle; Easy inspection, installation, and maintenance of the motor. Its main disadvantages are poor motor heat dissipation, poor grouping, and complex power supply equipment, manufacturing, and assembly.The classification and description of wire rope electric hoists. The components of wire rope electric hoists include: motor, transmission mechanism, drum, and sprocket. It can be roughly divided into four types based on the different positions of the motor and the drum. The pressed steel wire rope has high tensile strength, beautiful appearance, and fast speed. It only takes a few minutes to press and connect a set of steel wire ropes, greatly reducing labor intensity and improving work efficiency.The electric hoist with the motor installed outside the drum has the advantages of good grouping, high universality, easy change of lifting height, and convenient device inspection.The use of electric hoists is very extensive, but there are few personnel who can operate them correctly. It is recommended that everyone learn more about the relevant knowledge of electric hoists and make better use of various electric hoists in various fields.Main categoriesElectric hoists are mainly divided into: loop chain electric hoists, wire rope electric hoists (explosion-proof hoists), anti-corrosion electric hoists, double drum electric hoists, winches, micro electric hoists, group crane electric hoists, and multifunctional hoists.Application FieldsApplication areas: lifting, pulling, loading and unloading heavy objects, inverted welding of oil tanks, installation and movement of various large and medium-sized concrete, steel structures and mechanical equipment, suitable for construction and installation companies, civil engineering and bridge construction in factories and mines, power, shipbuilding, automobile manufacturing, construction, highways, bridges, metallurgy, mining, slope tunnels, shaft treatment and protection and other basic construction engineering mechanical equipment.